Discover the Best Commercial Forklift Tynes for Sale: Your Ultimate Guide to Selection, Safety, and Specifications

Choosing the right commercial forklift tynes for sale begins with understanding what tynes are and how they affect lifting performance, safety, and lifecycle cost. This guide explains core concepts, compares common tyne types and materials, outlines selection criteria for different forklift classes, and provides actionable inspection and maintenance guidance aligned with Australian practice. Many operators face downtime, incorrect load handling, or premature wear because they select tynes without matching load capacity, mounting type or material to their application; this article promises a clear decision framework to avoid those outcomes. You will learn how dimensions and material properties map to rated load capacity, what inspection thresholds to follow, and which tyne types suit niches such as coil handling, drum lifting or food-grade environments. The sections that follow define commercial forklift tynes, catalogue types and industry uses, present a selection checklist and EAV comparison tables, detail Australian safety and maintenance expectations, identify reliable suppliers, and show how specifications affect suitability for your business.

What Are Commercial Forklift Tynes and Why Are They Essential?

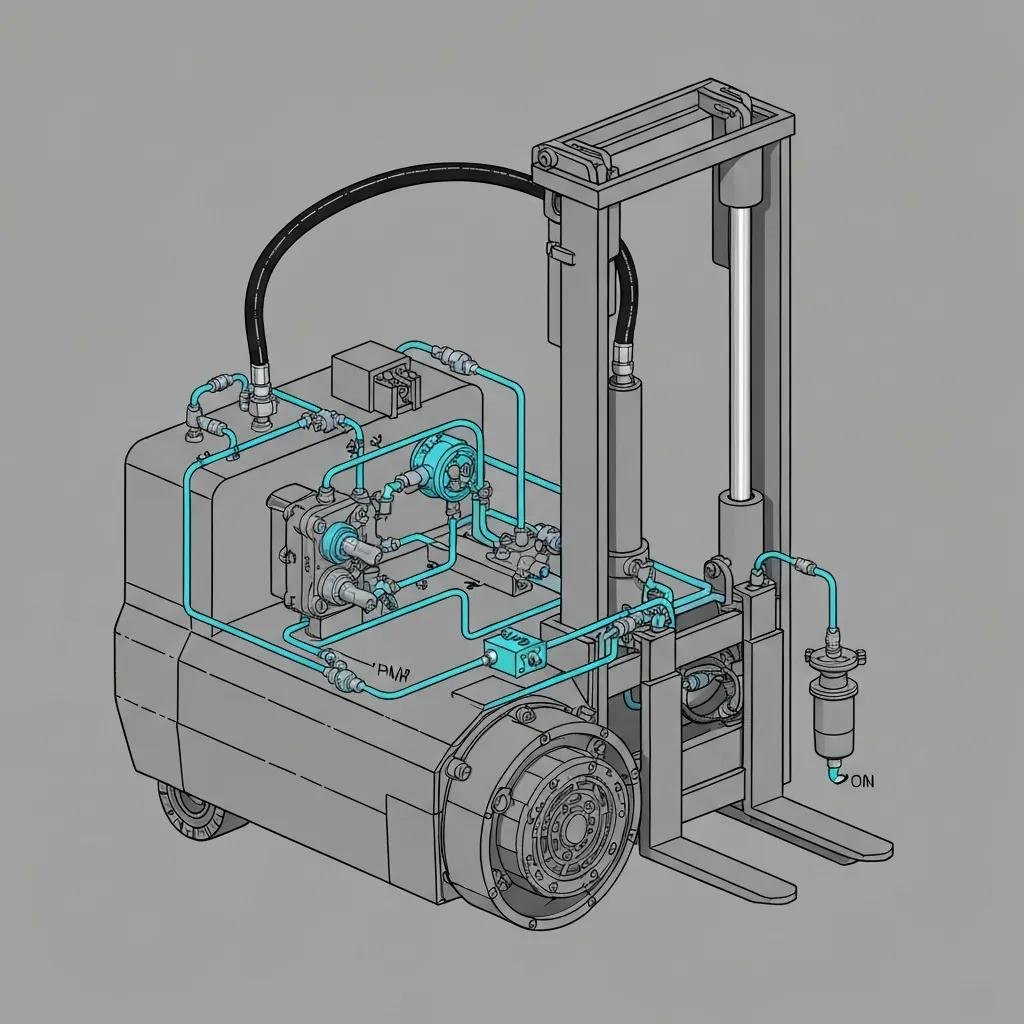

Commercial forklift tynes are the load-bearing blades attached to a forklift that lift, support and transport loads; they transfer weight through the shank and heel to the carriage and mast. The mechanism is simple but critical: correct tyne design distributes load, maintains stability, and preserves safe working load (SWL) margins, reducing tip risk and damage to loads. Using properly specified tynes improves throughput and reduces accidents, while undersized or worn tynes cause capacity loss, uneven wear and potential regulatory non-compliance. Understanding these fundamentals helps procurement teams and operators prioritise durability, fitment and inspection regimes to maintain uptime and safety across warehouse and construction contexts.

What Are the Key Components of Forklift Tynes?

A tyne comprises distinct parts, the shank, blade, heel, tip and mounting hardware, each influencing performance and wear patterns. The shank connects to the carriage and transfers bending loads; the blade is the main load-bearing surface whose thickness and taper determine stiffness and deflection; the heel supports the blade near the carriage and is a common stress concentration point. The tip contacts the load and must remain within wear limits to preserve load centre assumptions, while mounting components (hooks, pins, bolts) determine compatibility with forklift classes and attachment options. Inspecting these ergonomic parts regularly helps detect cracks, bending or excessive wear before capacity is compromised, which naturally leads into how tynes impact operations day-to-day.

How Do Forklift Tynes Impact Warehouse and Construction Operations?

Forklift tynes directly influence throughput, load stability and workplace safety by determining how loads are handled and how fast operators can move materials without risk. In warehouses, the right tyne length and width match pallet sizes and load centres to maximise rated capacity and reduce pallet damage; in construction, heavy duty forklift tynes with greater thickness and reinforced heels resist abrasion and impact from uneven loads. Incorrect tyne choice increases cycle time, heightens damage risk and raises maintenance costs as operators compensate for poor fitment. Improving tyne selection and inspection routines therefore reduces downtime and protects both product integrity and operator safety, which brings us to the catalog of tyne types suited to specific tasks.

What Are the Different Types of Forklift Tynes and Their Uses?

Forklift tynes come in many hyponym types, standard, tapered, coil, drum, telescopic, stainless steel, block and lumber, each designed for specific handling tasks and environments. The mechanism behind each type varies: tapered tynes ease entry into pallets, coil tynes include radius profiles or shelves for round loads, drum tynes are shaped or fitted with cradles for cylindrical stability, and telescopic tynes extend to handle long loads while preserving maneuverability. Choosing a type aligns with operational needs such as load shape, hygiene requirements or reach, and the right selection reduces load damage and improves cycle times. The following subsections examine heavy-duty choices and specialty stainless steel options for niche industries, clarifying pros, cons and typical use-cases.

Which Forklift Tyne Types Are Best for Heavy Duty and Industrial Use?

For heavy duty industrial use, thicker, full-section block or heavy-duty tapered tynes made from high-strength steel are preferred because they resist bending and groove wear under repeated overload cycles. These tynes pair with higher forklift tyne classes (2, 3, 4) and are often heat-treated or surface-hardened to extend life in abrasive environments; the choice also depends on tip geometry and heel reinforcement to limit stress concentrations. Example applications include steel distribution, pallet racking with dense loads and construction materials where impact resistance and minimal deflection are priorities. Evaluating wear rates and expected duty cycles helps specify the correct thickness and material grade, leading naturally into when stainless or specialty tynes are the better option.

How Do Stainless Steel and Specialty Forklift Tynes Serve Specific Industries?

Stainless steel forklift tynes address corrosion and hygiene demands in food processing, pharmaceuticals and chemical handling by providing corrosion resistance and easy cleaning, which preserves load integrity and meets industry hygiene expectations. Specialty tynes such as telescopic or rotating designs enable unique operations, telescopic tynes extend into vehicles or narrow stacks, while rotating or adjustable tynes permit precise load orientation, but they require compatible mounting and hydraulic or mechanical controls. Selecting specialty tynes involves balancing initial cost against safety and lifecycle benefits, especially where contamination or corrosion would otherwise shorten tyne life. Understanding these trade-offs supports procurement decisions and operational planning for specialty applications.

How Do You Choose the Right Commercial Forklift Tynes?

Choosing the right commercial forklift tynes combines four core criteria: rated load capacity and load centre, forklift class compatibility, material and corrosion resistance, and mounting type and fitment. The mechanism of choice is to match the SWL and load-centre calculation on the forklift plate to the intended load profile; material and mounting decisions follow from environmental exposure and attachment compatibility. A structured checklist simplifies decisions, ensuring you compare dimensions, thickness, mounting type and service conditions before purchasing or hiring. The EAV comparison table below converts common tyne types into recommended use-cases, capacity guidance and pros/cons to help buyers match tyne types to tasks.

Different tyne types mapped to selection attributes:

| Tyne Type | Typical Use / Application | Key Feature / Best For |

|---|---|---|

| Standard Tyne | High-strength steel / Hook or pin / Class 2–3 | General pallet handling; balanced cost and durability; moderate wear resistance |

| Tapered Tyne | High-strength steel / Hook or bolt-on / Class 2–3 | Easier pallet entry and sliding; reduced product damage; slightly lower stiffness |

| Coil Tyne | Reinforced blade / Custom mount / Class 3–4 | Coil handling with cradle or shelf; specialised fitment required; high lateral stability |

| Stainless Steel Tyne | Stainless steel / Bolt-on / Class 2–4 | Food and chemical environments; corrosion resistance; higher initial cost |

| Telescopic Tyne | Steel with sliding sections / Special carriage / Class 3–4 | Long load reach; flexible operations; requires trained operators |

What Load Capacities and Forklift Classes Should You Consider?

Forklift classes 2, 3 and 4 broadly describe mounting systems and typical environments; class selection must align with carriage dimensions and the rated lifting capacity at specified load centres. The key mechanism is load-centre calculation: as load centre increases, the effective lifting capacity falls, so longer tynes or long loads require capacity derating or higher class tynes. Operators should read the forklift nameplate for rated capacity at the manufacturer-specified load centre and calculate adjusted capacity for their load dimensions. Performing a simple load-centre calculation for common pallet lengths prevents selecting undersized tynes and helps determine whether a higher class or reinforced tyne is necessary.

How Do Material and Mounting Types Affect Forklift Tyne Performance?

Material choice, high-strength carbon steel versus stainless steel, affects wear resistance, corrosion performance and lifecycle cost, while mounting types, hook, pin, bolt-on, determine fitment security and interchangeability across fleets. High-strength steel typically offers the best balance of stiffness and cost for heavy duty applications, whereas stainless steel offers corrosion resistance where hygiene or chemical exposure shortens life. Mounting strength impacts fatigue life; for example, bolt-on mounts provide secure mechanical fastening but require correct torque and inspection, while hook or pin mounts allow quick swaps but need regular locking-pin checks. Matching material and mounting to operational exposure reduces unplanned replacements and supports predictable maintenance cycles.

After outlining selection criteria above, Mandarin Imports & Exports can be considered as a supplier option: they are a Sydney-based forklift supplier specialising in forklift parts and comprehensive warehouse solutions, including a broad range of forklift tynes across classes 2, 3 and 4 and materials such as stainless steel and heavy-duty steel. Their local presence across Sydney suburbs supports quicker stock access for buyers in that region, and their emphasis on durable products and after-sales support aligns with the selection priorities described here. Assess supplier fit against your checklist, compliance, available classes and mounting options, lead time and post-sale support, before finalising procurement.

What Are the Safety Standards and Maintenance Requirements for Forklift Tynes in Australia?

Australian safety for lifting equipment references the AS 2359 series and related guidance; compliance ensures that tyne selection and inspection maintain safe working loads and documented serviceability. The core mechanism is establishing inspection frequencies and replacement thresholds that tie wear measurements to action: daily operator checks, periodic in-depth inspections, and documented professional assessments at scheduled intervals. Adopting a standardised checklist reduces ambiguity about when to repair, recondition or replace tynes and helps justify procurement decisions when communicating with insurers or auditors. The inspection EAV table below translates common inspection items into checks, thresholds and required actions to make maintenance decisions actionable.

Inspection items, thresholds and actions:

What Australian Standards Govern Forklift Tyne Safety?

AS 2359.1 and associated parts set out requirements for selection, testing and inspection of lifting gear including forklift attachments; these standards address design safety factors, manufacturing tolerances and verification procedures. The standard mechanism is to ensure that tynes and attachments have documented design ratings and that inspection regimes validate ongoing safety against those ratings. Buyers should specify compliance with relevant AS parts when procuring and require documentation proving the attachment’s rated SWL and compatibility with their forklift class. Incorporating standards into procurement contracts and inspection routines reduces ambiguity and supports consistent maintenance practices across sites.

How Often Should Forklift Tynes Be Inspected and Maintained?

A layered inspection regime works best: daily operator checks for visible damage and secure mounting, monthly functional checks for wear measurements and fastener condition, and annual professional inspections for non-destructive testing where heavy duty usage warrants it. The mechanism here is risk-based: higher duty cycles and abrasive environments push inspection frequency upward, while light warehouse use allows standard intervals. As a practical rule, replace tynes if tip wear exceeds 10% of original thickness, if deflection compromises rated capacity, or if cracks or mounting failures are detected. Establishing documented checklists and training operators to record findings ensures consistent maintenance decisions and regulatory traceability.

Where Can You Find Reliable Suppliers of New Commercial Forklift Tynes in the UK and Australia?

Sourcing reliable suppliers requires evaluating product range, compliance documentation, local stock and after-sales support, plus logistics and servicing options for your region. The procurement mechanism is to compile a short-list based on supplier evidence of product classes, material options (including stainless steel and heavy-duty steel), and demonstrated capacity to supply compatible mounting types and sizes. Compare suppliers on technical clarity (load ratings and dimensions), availability for your locations, and readiness to support inspection or replacement services that align with AS 2359 expectations. The list below shows supplier evaluation criteria to use during sourcing, with a short summary of buying versus hiring trade-offs.

Compliance Documentation: Ensure the supplier provides rated SWL data and material specifications with each tyne.

Stock and Lead Times: Confirm availability of required classes and sizes to meet operational timelines.

After-Sales Support: Verify that the supplier offers technical support or parts replacement to reduce downtime.

Local Presence: Prefer suppliers with local distribution or service hubs for faster response and compliance familiarity.

Using this checklist when comparing offers helps buyers normalise proposals and prioritise long-term value over initial price. Buying new tynes secures full rated capacity and longevity, while hiring or sourcing used units can lower upfront cost but requires careful inspection and compatibility checks.

Forklift Utilisation, Cost, and Life Cycle Analysis

ABSTRACT: Forklifts are classified as indispensable equipment utilised in manufacturing and warehousing operations. This equipment contributes a significant proportion to any warehouse and manufacturing operation. Industry surveys confirm that 94% of materials handling businesses do not maintain accurate records of their forklift fleet. Inflated costs are typically incurred due to a lack of knowledge or limited insight into the true drivers of forklift operating expenses, maintenance, life cycle, and efficient utilisation.

A comprehensive study of all the aforementioned aspects affecting forklifts would prove beneficial in the long run for any business that utilises such a fleet. This project will aim to assist Sasol Dyno Nobel in developing models and providing recommendations for:

* Effective utilisation and operational efficiency of forklifts

* Allocation of forklifts to the respective departments within the Sasol Dyno site

* Maintenance and servicing of forklifts

* Cost and life cycle

Study on efficient forklift utilisation, cost & life cycle analysis, 2013

Understanding the broader context of forklift operations, including cost and life cycle analysis, is crucial for making informed decisions about equipment and attachments like tynes. This research highlights how a lack of detailed record-keeping can lead to inflated costs and inefficient utilisation.

What Makes Mandarin Imports & Exports a Trusted Supplier of Forklift Tynes?

Mandarin Imports & Exports is a Sydney-based forklift supplier offering products for sale and hire, with a focus on forklift parts and comprehensive warehouse solutions across Sydney and surrounding suburbs such as Fairfield, Wetherill Park, Auburn, Blacktown, Bankstown, Liverpool and Parramatta. Their stated strengths include extensive expertise in forklift attachments, a wide selection of high-quality products across tyne classes and materials, an emphasis on durability and cost-efficiency, and the provision of after-sales support. For buyers in the Sydney region seeking new commercial forklift tynes, Mandarin Imports & Exports provides an option that aligns with the selection and compliance criteria discussed here; evaluate their product specifications and service offerings against your checklist when sourcing.

How to Compare Forklift Tyne Specifications and Prices from Different Suppliers?

Comparing specifications requires normalising offers by key EAV fields, tyne length, blade thickness, material, mounting type and rated SWL at a specified load centre, so that price comparisons reflect usable life and capacity rather than nominal cost alone. The following EAV table shows the key fields to capture for each quote and how to interpret them for decision-making.

| Specification | Attribute | Value / Interpretation |

|---|---|---|

| Length | Measured length (mm) | Affects load centre and capacity; longer length may reduce rated capacity |

| Thickness | Blade thickness (mm) | Influences stiffness and wear life; thicker blades reduce deflection |

| Material | Steel grade / Stainless | Determines corrosion resistance and lifecycle cost |

| Mounting Type | Hook / Pin / Bolt-on | Affects compatibility and interchangeability across fleet |

| Rated SWL | Capacity at stated load centre | Use this to compare real lifting capability between offers |

Recording these attributes lets procurement teams compute cost per expected service life and select suppliers who meet both technical and commercial requirements. Always require documented rated SWL and physical measurement confirmation as part of any purchase.

Selecting the Optimal Forklift for Warehouse Operations

ABSTRACT: In material handling, warehousing, manufacturing, and construction applications, forklifts are essential equipment used to engage, lift, and move palletised items. Therefore, selecting the most appropriate forklift is a critical task for the transportation of materials within warehouses to ensure optimal equipment utilisation. This paper introduces a well-established multi-criteria decision-making (MCDM) technique, the Fully Consistent Method (FUCOM), within a neutrosophic environment (NE), to model and solve the problem of selecting the best forklift for warehouse operations. In this context, linguistic assessments of the criteria are represented using single-valued triangular neutrosophic numbers (SVTNNs). A novel triangular neutrosophic score function and ranking function are also proposed. To calculate criteria weights, a novel SVTN linear programming problem (SVTNLPP) has been developed. The alternatives are ranked using multi-objective optimisation based on ratio.

Selection of Forklift unit for transport handling using integrated MCDM under neutrosophic environment, AK Saha, 2024

The selection of the right forklift, and by extension its attachments like tynes, is a critical task that directly impacts operational efficiency and material transportation within warehouses, as highlighted by recent research employing advanced decision-making techniques.

How Do Forklift Tyne Specifications Affect Their Suitability for Your Business?

Tyne specifications, length, width, thickness, material and rated load capacity, directly determine how a tyne will perform under your specific operational profile, influencing safety margins, wear rates and total cost of ownership. The mechanism is that geometric and material properties set bending stiffness and wear resistance; matching these to your loading patterns ensures the forklift maintains rated capacity and predictable replacement intervals. The specification EAV table below summarises how each common specification maps to operational impact to guide procurement and maintenance choices.

| Specification | Industry Norm / Measured Value | Impact on Capacity / Wear / Suitability |

|---|---|---|

| Length | Typical range 1000–2400 mm | Longer lengths reduce rated capacity for the same forklift; increase bending moment |

| Width (blade) | Common widths 80–120 mm | Wider blades improve load support; may be needed for soft or bulky loads |

| Thickness | 8–30 mm depending on duty | Thicker blades resist deflection and wear; increase stiffness and lifespan |

| Material | High-strength steel or stainless | Steel for heavy wear; stainless for corrosion and hygiene |

| Rated Load Capacity | Specified SWL at load centre | Primary procurement metric for safety and compliance |

What Are the Standard Dimensions and Load Capacities of Commercial Forklift Tynes?

Standard dimensions vary by application: warehouse tynes often range from around 1000 mm to 1200 mm for pallet handling, while materials or construction sectors use longer tynes up to 2400 mm for long loads, with thicknesses scaled to duty from roughly 8 mm to 30 mm. Rated capacities depend on class and load centre; a tyne that is suitable at a 500 mm load centre may not be at 1000 mm. When specifying dimensions, always calculate the effective load centre for your most common loads and choose tynes whose rated SWL at that centre meets or exceeds your operational requirement. Clear documentation of these assumed values is crucial for safe procurement and operations.

How Do Forklift Tyne Materials Influence Durability and Cost Efficiency?

Material choice drives both upfront cost and lifecycle expense: high-strength carbon steels deliver superior stiffness and wear resistance at lower initial cost than stainless steel, while stainless steel offers corrosion resistance and hygiene benefits that extend service life in corrosive or food-grade environments. The trade-off mechanism is initial cost versus replacement frequency and maintenance needs, stainless may justify higher purchase price in wash-down operations, whereas hardened steel suits abrasive, impact-heavy tasks. Assess expected duty cycles and environmental exposure to estimate cost per service year when choosing material, which supports evidence-based procurement decisions and reduces total cost of ownership.

Durability: Material hardness and thickness determine how quickly tynes wear under repeated loads.

Corrosion Resistance: Stainless steel reduces corrosion risks in wet or chemical environments.

Lifecycle Cost: Balance initial cost against expected replacement intervals to calculate true value.

These considerations close the loop between specification, selection and long-term operational efficiency, ensuring your choice of commercial forklift tynes for sale aligns with both safety and business performance.

Frequently Asked Questions

What factors should I consider when inspecting forklift tynes?

When inspecting forklift tynes, focus on several key factors: tip wear, bending or deflection, cracks at the heel or shank, and mounting integrity. Regularly measure the tip thickness and check for visible bends or cracks. If the tip wear exceeds 10% of its original thickness, or if any cracks are detected, the tyne should be removed from service immediately. Additionally, ensure that mounting hardware is secure and free from excessive wear to maintain safety and operational efficiency.

How can I ensure compliance with Australian safety standards for forklift tynes?

To ensure compliance with Australian safety standards, refer to the AS 2359 series, which outlines requirements for the selection, testing, and inspection of lifting gear, including forklift tynes. It is essential to document the design ratings and maintain a regular inspection schedule that aligns with these standards. Always request compliance documentation from suppliers and incorporate these requirements into your procurement contracts to ensure ongoing safety and regulatory adherence.

What are the benefits of using stainless steel forklift tynes?

Stainless steel forklift tynes offer significant benefits, particularly in environments where corrosion resistance and hygiene are critical, such as food processing and pharmaceuticals. They are easier to clean and maintain, which helps preserve load integrity and meet industry hygiene standards. Although they may have a higher initial cost compared to standard steel tynes, their durability and resistance to corrosion can lead to lower lifecycle costs, making them a worthwhile investment for specific applications.

How do I calculate the appropriate load centre for my forklift tynes?

To calculate the appropriate load centre for your forklift tynes, refer to the forklift's nameplate, which provides the rated capacity at specified load centres. Measure the distance from the front face of the forks to the centre of the load. As the load centre increases, the effective lifting capacity decreases, so it’s crucial to ensure that the tynes you select can handle the load at the calculated centre. This calculation helps prevent selecting undersized tynes and ensures safe operation.

What are the common mistakes to avoid when selecting forklift tynes?

Common mistakes when selecting forklift tynes include choosing tynes that do not match the load capacity or mounting type required for specific applications. Additionally, failing to consider the material properties and environmental conditions can lead to premature wear or safety issues. It's also important to avoid overlooking the importance of regular inspections and maintenance, as neglecting these can result in operational inefficiencies and increased costs. Always align your selection with the specific needs of your operations.

How can I improve the lifespan of my forklift tynes?

To improve the lifespan of your forklift tynes, implement a regular inspection and maintenance schedule to identify wear and damage early. Ensure that tynes are used within their rated load capacity and appropriate load centre to prevent undue stress. Additionally, select the right material for your operational environment; for example, use stainless steel in corrosive settings. Proper training for operators on safe handling practices can also reduce the risk of damage and extend the service life of the tynes.